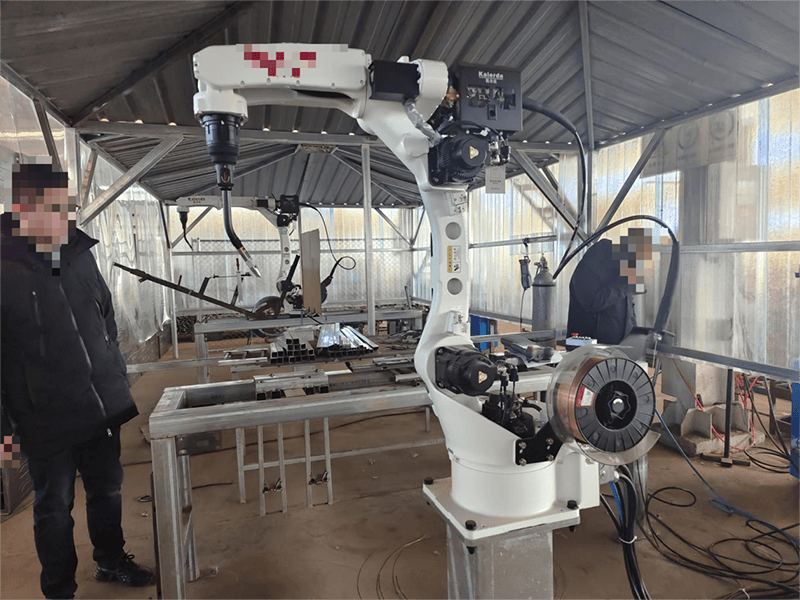

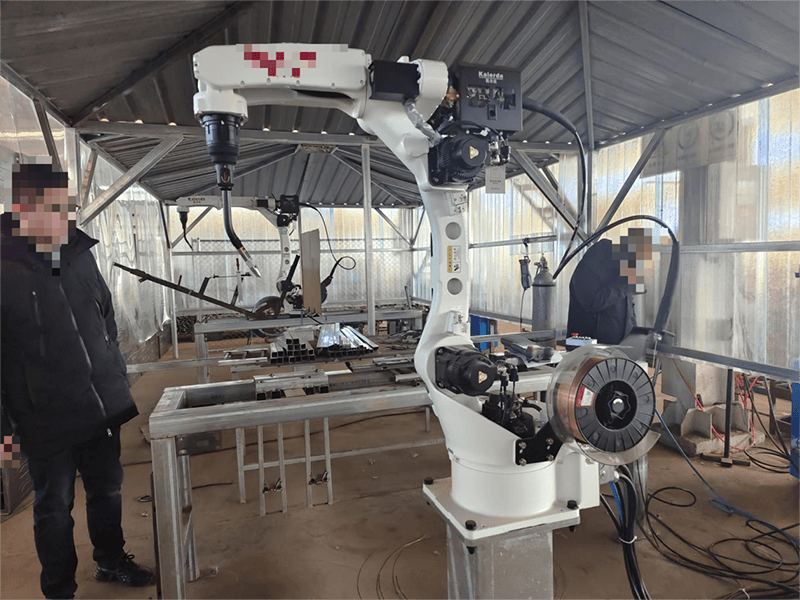

This kind of robot does not have the workpiece assembly error, thermal deformation in the welding process environment change, as well as the work object change should ability, therefore, develop a new generation of has a variety of sensing function, can automatically formulate trajectory, welding moment attitude and welding parameters of intelligent robot will become the main development direction.

This kind of robot does not have the workpiece assembly error, thermal deformation in the welding process environment change, as well as the work object change should ability, therefore, develop a new generation of has a variety of sensing function, can automatically formulate trajectory, welding moment attitude and welding parameters of intelligent robot will become the main development direction.

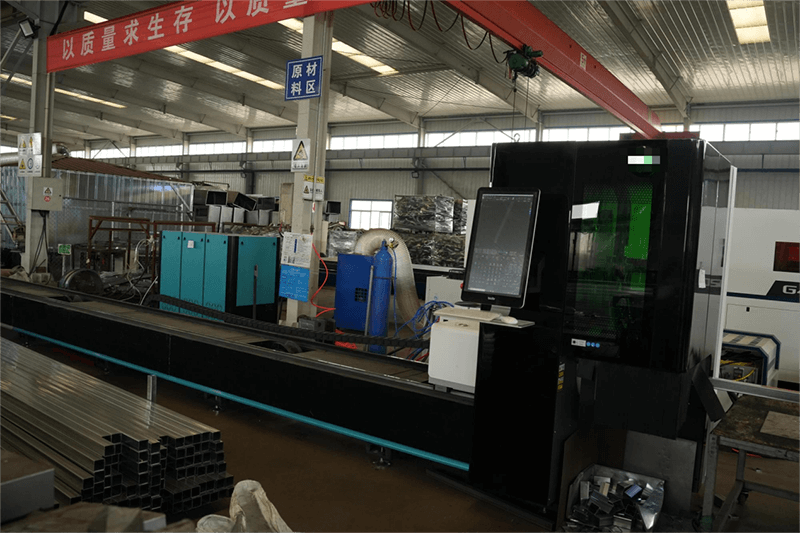

The development of new materials will be developed towards high efficiency, high performance (including good weldability) and environmental benefit. Welding will develop better welding process, developed a better welding power supply and develop the corresponding control technology, improve the degree of automation and expand the application scope of the robot: reduce the scrap rate and repair rate, reduce the welding cost, improve the production efficiency (such as: reduce, after preheating, heat, avoid welding overheating, etc.), eliminate the concept of "welding is a manufacturing process obstacle".

Post time: Jun-18-2024